Exploring the Power of Digital Twin Technology: Enhancing Efficiency and Productivity

- October 27, 2023

- XR Technology

Digital twin technology is revolutionizing industries, offering a glimpse into the future of efficiency and productivity. By creating virtual replicas of physical objects or systems, businesses can optimize their operations, predict maintenance needs, and minimize downtime. With its ability to simulate real-world scenarios and perform analytics, this technology enables organizations to make informed decisions and streamline workflows.

From manufacturing to healthcare, the applications of digital twin technology are diverse, promising a future where efficiency and productivity are taken to new heights.

Overview of Digital Twin Technology

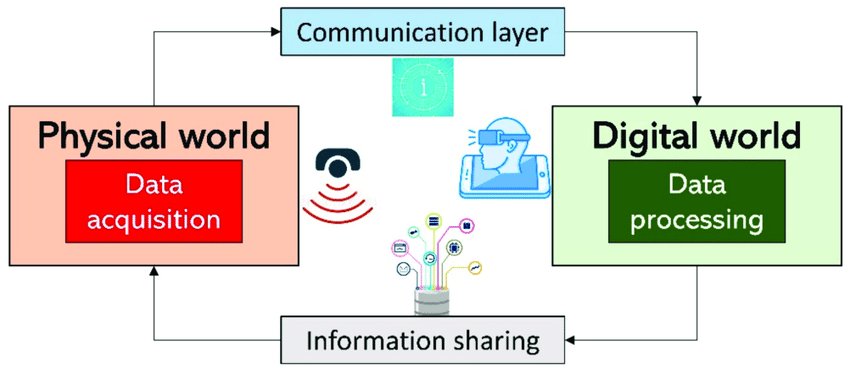

Digital twin technology is a powerful tool that enables the creation of virtual replicas of physical systems or assets. By connecting these virtual replicas with real-time data from sensors and other sources, organizations can gain valuable insights, optimize performance, and make informed decisions.

For example, in the manufacturing industry, digital twin technology can help identify opportunities for process improvement by simulating different scenarios and predicting outcomes. In the healthcare sector, digital twins of patients can be used to personalize treatment plans and predict disease progression.

Definition of Digital Twin

A digital twin is a virtual representation of a physical object, system, or process that allows for real-time monitoring, analysis, and control. By capturing and analyzing data from its physical counterpart, digital twins provide valuable insights and enable optimization, predictive maintenance, and simulations.

For example, in manufacturing, a digital twin can simulate production scenarios to identify bottlenecks and optimize workflows. Similarly, in healthcare, digital twins can be used to simulate patient conditions and evaluate potential treatment options. The practical applications of digital twins extend across various industries, facilitating improved efficiency, cost savings, and enhanced decision-making capabilities.

Importance of Digital Twin Technology

Digital Twin technology offers incredible value in various industries. By creating a virtual replica of physical assets or systems, businesses can gather real-time data and gain invaluable insights.

For example, in manufacturing, Digital Twin enables companies to optimize processes, identify potential faults, and improve overall performance. It also reduces downtime and maintenance costs. In healthcare, Digital Twin models can simulate patient conditions and assist in personalized treatment plans. From smart cities to logistics, this technology continues to revolutionize operations by enhancing efficiency, reducing risk, and enabling predictive maintenance. Its potential for transforming industries is undeniable.

Benefits of Digital Twin Technology

Digital Twin Technology offers numerous benefits to various industries.

Firstly, it allows for real-time monitoring and analysis of physical assets, enabling timely maintenance and reduced downtime.

For example, in the manufacturing sector, Digital Twin can track machine performance and identify potential issues before they escalate, significantly improving efficiencies.

Additionally, Digital Twins facilitate virtual testing and simulation, eliminating the need for physical prototypes. This lowers costs and accelerates product development cycles. Furthermore, Digital Twins enable predictive analytics, optimizing operations by forecasting patterns and trends. This empowers organizations to make data-driven decisions and achieve greater productivity.

Applications of Digital Twin Technology

Digital Twin Technology finds applications in various industries, offering practical benefits that improve operational efficiency and productivity. In manufacturing, digital twins enable real-time monitoring of production lines, facilitating predictive maintenance and reducing downtime. In healthcare, digital twins support personalized medicine by modeling patient behavior, allowing physicians to make more accurate diagnoses and develop tailored treatment plans.

The technology also plays a crucial role in urban planning, where digital twins simulate traffic patterns and energy consumption, aiding in the development of sustainable cities. Its widespread applications across industries demonstrate the versatility and value of digital twin technology in optimizing processes and driving innovation.

Challenges and Considerations

Implementing a Digital Twin comes with its fair share of hurdles. One notable challenge is the integration of various systems and data sources, as compatibility issues often arise. For instance, a company may face difficulties in synchronizing multiple machines, each operating on different software platforms.

Additionally, ensuring data accuracy and reliability poses another obstacle. Data discrepancies can arise due to sensor malfunctions or human error, impeding the accuracy of the digital representation. These challenges highlight the importance of meticulous planning and quality assurance to ensure seamless implementation and reliable performance of a Digital Twin.

Future Trends and Developments

Future Trends and Developments in the realm of Digital Twin are shaping the way industries operate. For instance, advanced sensor technology allows for real-time monitoring and analysis of physical assets, enabling businesses to optimize operations and reduce maintenance costs.

Additionally, the integration of Artificial Intelligence (AI) and machine learning with Digital Twin technology enhances predictive capabilities, allowing for proactive maintenance and improved decision-making. Furthermore, the emergence of cloud computing enables seamless data sharing and collaboration across different stakeholders, leading to increased efficiency and innovation. These trends collectively drive the growth and adoption of Digital Twin technology across various sectors, revolutionizing the way we understand and interact with physical assets.

Over to You

Digital twin technology is gaining prominence as a tool to enhance efficiency and productivity in various industries. By creating virtual replicas of physical assets or systems, organizations can simulate, monitor, and optimize their operations in real-time. This technology enables businesses to identify and rectify potential issues, leading to improved performance and cost-savings.

Through data analytics and machine learning, digital twins provide valuable insights and predictive capabilities,allowing organizations to make proactive decisions and streamline processes. Consequently, digital twin technology holds immense potential for revolutionizing industries and is set to play a crucial role in the future of efficient and productive operations.